Description du produit:

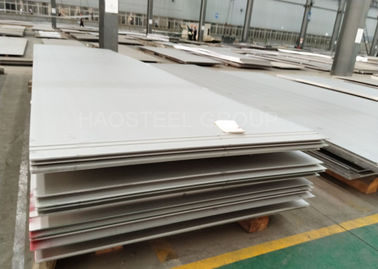

The Alloy Steel Metal offered in the form of Inconel 600 Alloy Steel Plate Sheets represents a high-performance Metal Alloy Steel solution designed to meet the rigorous demands of various industrial applicationsCe produit en acier allié est réputé pour ses propriétés mécaniques exceptionnelles, sa résistance à la corrosion supérieure et sa stabilité thermique exceptionnelle.ce qui en fait le choix préféré pour les environnements où la résistance et la durabilité sont primordiales.

L'une des caractéristiques caractéristiques de cet alliage d'acier est son traitement thermique, qui consiste à éteindre et à tempérer.Ce traitement thermique améliore les propriétés mécaniques du matériau en augmentant sa dureté et sa résistance tout en conservant une ductilité et une ténacité adéquates.Le procédé d'éteinture et de trempage assure que les plaques d'acier inconel 600 présentent un équilibre optimal entre résistance et souplesse.qui est essentiel pour les applications impliquant des contraintes élevées et des charges fluctuantes.

Les tôles en acier allié Inconel 600 ont un point de fusion compris entre 1425 et 1540 °C.Cette température de fusion élevée souligne la capacité du métal à résister à des environnements thermiques extrêmes sans déformation significative ou perte d'intégrité mécaniqueUne telle résistance thermique rend cet acier allié métallique très adapté pour une utilisation dans l'aérospatiale, la production d'énergie, le traitement chimique,et autres industries nécessitant des matériaux capables de fonctionner à température élevée.

Une autre caractéristique importante de cet acier allié est sa résistance impressionnante, qui varie de 350 à 1000 MPa.Cette large gamme de valeurs de résistance au rendement permet une personnalisation en fonction des exigences spécifiques de l'application, offrant aux ingénieurs et aux concepteurs une souplesse dans le choix des matériaux.La résistance élevée garantit que le métal allié d'acier peut résister à des contraintes mécaniques importantes sans déformation permanente, ce qui contribue à la longévité et à la fiabilité des composants fabriqués à partir de celui-ci.

La personnalisation est l'un des principaux avantages offerts par ces produits en alliage d'acier.Les dimensions des plaques d'acier Inconel 600 peuvent être adaptées aux besoins précis de différents projetsCette capacité de personnalisation garantit que l'acier allié métal peut être parfaitement intégré dans divers processus de fabrication,réduire les déchets et optimiser l'utilisation des matériaux.

En plus de ses propriétés mécaniques et thermiques, cet acier allié présente une excellente résistance à la corrosion, en particulier dans des environnements chimiques difficiles.La composition de l'acier allié Inconel 600 est conçue pour résister à l'oxydation et à la corrosion causées par l'exposition à des acidesCette propriété prolonge considérablement la durée de vie des composants fabriqués à partir de cet alliage d'acier, réduisant les coûts d'entretien et les temps d'arrêt.

La polyvalence des plaques d'acier en alliage Inconel 600 les rend adaptées à un large éventail d'applications.dans les centrales électriques pour échangeurs de chaleur et générateurs de vapeur, et dans l'industrie chimique pour les réacteurs et les systèmes de tuyauterie.Les procédés de traitement thermique de qualité supérieure garantissent que ce métal allié d'acier répond aux critères de performance stricts exigés par ces secteurs..

En résumé, les plaques d'acier allié Inconel 600 représentent un produit de qualité supérieure en acier allié caractérisé par un traitement thermique robuste par étanchement et trempage,point de fusion élevé entre 1425 et 1540 °CCet acier allié se distingue par un choix exceptionnel pour les applications nécessitant une résistance durable, résistante à la chaleur,et matériaux résistants à la corrosionSes propriétés supérieures et son adaptabilité en font une ressource indispensable pour les industries axées sur la qualité et les performances.

Paramètres techniques:

| Point de fusion |

1425 à 1540 °C |

| Résistance à la traction |

600 à 1200 MPa |

| Saldabilité |

Modérée |

| Contenu en carbone |

00,05% à 2,0% |

| Traitement thermique |

Éteindre et tempérer |

| Les colis |

Dans des paquets de matériaux imperméables |

| Épaisseur |

3 à 200 mm |

| Résistance à la corrosion |

Modéré à élevé |

| Résistance au rendement |

350 à 1000 MPa |

| Grade |

Inconel 600, 601, 625, 800, 800HT, 800H, 901, 925, 926, 718 |

Applications:

Le métal allié d'acier, spécialement fabriqué à partir de la série Inconel de haute qualité, y compris les catégories 600, 601, 625, 800, 800ht, 800H, 901, 925, 926 et 718,offre des performances exceptionnelles dans un large éventail d'applications industriellesAvec des spécifications certifiées par BV et SGS, ce métal en alliage d'acier garantit la qualité et la fiabilité, ce qui en fait le choix préféré pour les environnements exigeants.,La teneur en carbone, qui varie entre 0,05% et 2,0%,améliore sa résistance et sa durabilité tout en conservant une soudabilité modérée, ce qui facilite la fabrication et l'assemblage.

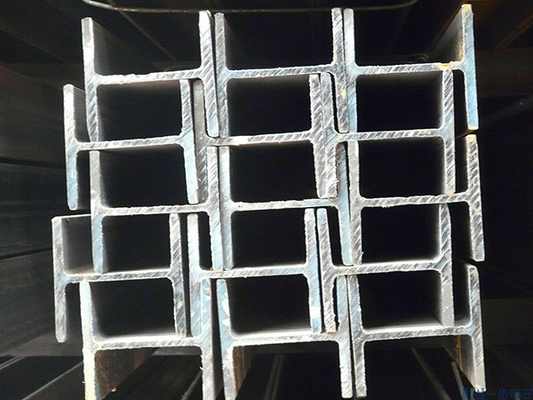

La polyvalence de ce métal en alliage d'acier le rend idéal pour des applications telles que l'aérospatiale, la production d'énergie, le traitement chimique et le génie maritime.Les qualités de haute performance des grades Inconel comme 718 et 625 assurent une résistance aux températures extrêmes et à la corrosion.Dans la production d'énergie, le métal allié d'acier résiste aux environnements difficiles dans les turbines à gaz et les réacteurs nucléaires,où sa capacité à maintenir son intégrité mécanique à température élevée est essentielleLes usines chimiques s'appuient sur ce métal allié d'acier pour construire des réacteurs, des échangeurs de chaleur et des systèmes de tuyauterie en raison de son excellente résistance à la corrosion dans des environnements acides et oxydants.

En génie maritime, la durabilité du métal allié d'acier contre la corrosion de l'eau de mer le rend approprié pour la construction navale, les plates-formes pétrolières offshore et les usines de dessalement.La soudabilité modérée de ce métal allié d'acier permet également la fabrication de structures complexes et de réparations in situ.En outre, sa large gamme d'épaisseurs permet une personnalisation dans les machines lourdes, les composants automobiles et les projets d'infrastructure,où la force et la longévité sont primordialesDans l'ensemble, la combinaison de la qualité certifiée, des options de qualité diverses et des propriétés physiques adaptables de l'acier allié métallique garantit qu'il répond aux exigences rigoureuses de divers scénarios industriels.fournir des solutions fiables pour les applications quotidiennes et spécialisées.

Personnalisation:

Notre produit en acier allié offre d'excellents services de personnalisation adaptés à vos besoins spécifiques.ce métal allié d'acier est adapté à divers procédés de fabricationL'acier en alliage métallique est conforme aux spécifications BV et SGS, garantissant des normes de qualité élevées et des propriétés de matériau cohérentes.

Le métal allié d'acier présente une résistance à la traction allant de 600 à 1200 MPa et une résistance au rendement comprise entre 350 et 1000 MPa, offrant des performances mécaniques supérieures pour les environnements exigeants.En plus, son point de fusion varie de 1425 à 1540 °C, ce qui rend ce métal allié d'acier idéal pour les applications à haute température.Faites confiance à nos services de personnalisation pour fournir la solution idéale en acier allié métallique adaptée à vos besoins.

Emballage et expédition

Nos produits en alliage d'acier métallique sont soigneusement emballés pour assurer une protection maximale pendant le transport.,Les produits sont ensuite placés dans des caisses en bois renforcées et résistantes ou dans des cartons lourds, selon la taille et le poids de l'envoi.

Pour plus de sécurité, des déshydratants et des papiers antirouille sont inclus à l'intérieur de l'emballage pour préserver la qualité du métal et prévenir les dommages causés par l'humidité.Tous les colis sont clairement étiquetés avec des instructions de manutention et des détails sur le produit pour faciliter une logistique en douceur.

Nous offrons des options d'expédition flexibles, y compris le fret maritime, le fret aérien et le transport terrestre, adaptées aux exigences de livraison de nos clients dans le monde entier.Notre équipe logistique assure l'expédition en temps opportun et vous tient informé tout au long du processus d'expédition, fournissant des informations de suivi pour une transparence totale.

À leur arrivée, les clients sont invités à inspecter immédiatement l'emballage et les produits et à signaler tout dommage ou décalage dans les délais prescrits afin de permettre une résolution rapide.

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!