Description du produit :

La barre en acier inoxydable est un produit polyvalent et de haute qualité conçu pour répondre à un large éventail de besoins industriels et manufacturiers. Fabriquée avec précision et respectant des normes de qualité strictes telles que ASTM, EN et JIS, cette barre en acier inoxydable offre une durabilité, une résistance et une résistance à la corrosion exceptionnelles. Disponible dans des spécifications allant de Φ3mm à Φ150mm, elle répond à diverses applications, assurant flexibilité et fiabilité pour différents projets d'ingénierie.

L'une des caractéristiques importantes de ce produit est son niveau de dureté impressionnant de HRB 90, qui garantit une robustesse et des performances durables, même dans des conditions exigeantes. Qu'elle soit utilisée dans la construction, l'automobile, les machines ou d'autres secteurs industriels, la barre en acier inoxydable offre d'excellentes propriétés mécaniques qui contribuent à l'efficacité et à la sécurité globales du produit final.

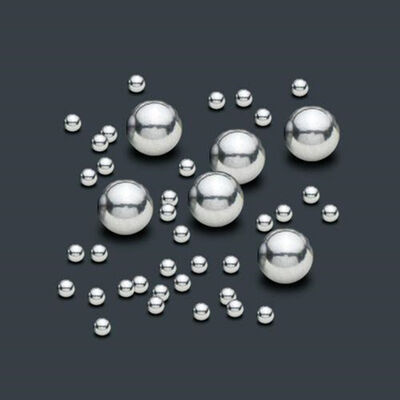

La barre ronde en acier inoxydable est particulièrement appréciée pour son diamètre uniforme et sa finition de surface lisse, ce qui en fait un choix idéal pour les travaux d'ingénierie de précision et d'usinage. Sa forme ronde permet une manipulation facile et une polyvalence dans des applications telles que les arbres, les goupilles, les fixations et les composants structurels. La qualité constante et la précision dimensionnelle de ce produit aident les fabricants à obtenir des tolérances serrées et des performances supérieures du produit final.

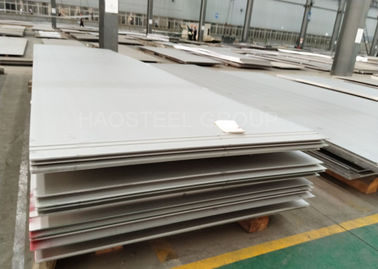

En plus de la barre ronde en acier inoxydable, la gamme de produits comprend également la barre noire en acier inoxydable, connue pour sa finition distinctive en oxyde noir. Cette barre noire améliore non seulement l'attrait esthétique, mais offre également une protection supplémentaire contre l'usure et la corrosion. Elle est particulièrement adaptée aux applications où l'apparence et les performances sont essentielles, offrant une solution robuste pour les utilisations décoratives et fonctionnelles.

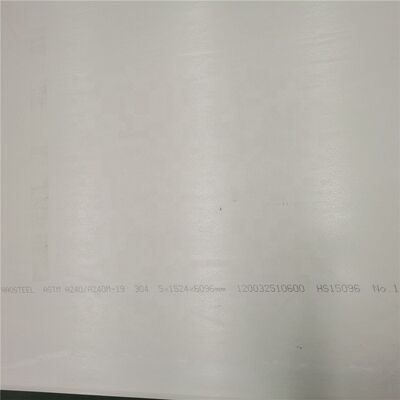

Pour les applications nécessitant une douceur de surface améliorée et une apparence raffinée, la barre de meulage polie en acier inoxydable est une excellente option. Cette variante subit un processus spécialisé de polissage et de meulage qui se traduit par une finition miroir et une intégrité de surface améliorée. La barre de meulage polie est largement utilisée dans les industries où la qualité esthétique et la propreté de la surface sont primordiales, comme dans les ustensiles de cuisine, les instruments médicaux et les éléments architecturaux haut de gamme.

Un autre avantage important du produit de barre en acier inoxydable est le délai d'exécution efficace, généralement compris entre 5 et 10 jours. Ce délai d'exécution rapide garantit que les clients reçoivent leurs commandes rapidement, minimisant les temps d'arrêt et facilitant l'achèvement rapide des projets. L'engagement du fabricant à une livraison rapide sans compromettre la qualité fait de cette barre en acier inoxydable un choix privilégié pour les besoins d'approvisionnement urgents et à grande échelle.

De plus, les barres en acier inoxydable sont produites à l'aide de techniques de fabrication avancées et subissent des processus rigoureux de contrôle de la qualité pour garantir la conformité aux normes internationales telles que ASTM, EN et JIS. Ce dévouement à l'assurance qualité garantit que chaque lot de barres maintient des propriétés mécaniques, une composition chimique et une précision dimensionnelle constantes, répondant aux normes les plus élevées de l'industrie.

En résumé, le produit de barre en acier inoxydable offre une solution complète pour diverses applications industrielles. Sa disponibilité en différentes tailles de Φ3mm à Φ150mm, combinée à une dureté de HRB 90, garantit qu'elle peut résister aux environnements difficiles et aux contraintes mécaniques. L'inclusion des variantes de barres rondes en acier inoxydable, de barres noires en acier inoxydable et de barres de meulage polies en acier inoxydable offre aux clients de multiples options adaptées à leurs exigences spécifiques.

Que vous ayez besoin d'un matériau fiable pour les composants structurels, l'usinage de précision, les applications esthétiques ou les pièces résistantes à la corrosion, cette barre en acier inoxydable se distingue comme un choix supérieur. Grâce à son respect des normes de qualité, ses délais d'exécution rapides et ses spécifications polyvalentes, elle offre une valeur et des performances exceptionnelles aux fabricants et aux ingénieurs.

Applications :

La barre en acier inoxydable HAOSTEEL est un produit polyvalent et de haute qualité conçu pour répondre aux divers besoins de diverses industries. Fabriquées à Jiangsu et certifiées selon la norme ISO90001, ces barres en acier inoxydable sont disponibles dans une large gamme de modèles, notamment 201, 202, 301, 304, 304L, 316, 316L, 310S, 321, 347H, 317L, 316Ti, 2205, 2507, 904L, 410, 420, 430 et 430F. Avec des diamètres allant de 3 mm à 600 mm, ces barres conviennent à de nombreuses applications nécessitant une résistance exceptionnelle à la rouille et une durabilité.

L'une des principales occasions d'application des barres en acier inoxydable HAOSTEEL se trouve dans les secteurs de l'industrie lourde et de la fabrication où les matériaux haute performance sont cruciaux. La barre de meulage polie en acier inoxydable est particulièrement appréciée dans la fabrication automobile, aérospatiale et de machines en raison de ses excellentes propriétés d'usinabilité et de sa résistance à la corrosion. Ces barres peuvent être utilisées pour produire des composants de précision qui exigent une finition brillante et polie, faisant de la barre brillante en acier inoxydable un matériau essentiel dans la production de pièces décoratives et fonctionnelles.

Dans les projets de construction et d'architecture, les barres en acier inoxydable de HAOSTEEL offrent une résistance structurelle combinée à un attrait esthétique. La haute résistance à la rouille assure la longévité des installations extérieures et des environnements exposés aux intempéries. La barre de meulage polie en acier inoxydable est également largement utilisée dans la fabrication d'équipements de cuisine, de dispositifs médicaux et de machines de transformation des aliments où l'hygiène et la résistance à la corrosion sont primordiales.

Avec une capacité d'approvisionnement de 5000 tonnes par mois et une quantité minimale de commande de seulement 1 tonne, HAOSTEEL offre des options d'achat flexibles pour répondre aux exigences industrielles à grande échelle et aux productions en petits lots. L'emballage en bois d'exportation assure une livraison en toute sécurité dans un délai de 5 à 10 jours et un délai de livraison global de 7 à 15 jours. Les conditions de paiement, notamment T/T, L/C et Western Union, offrent des méthodes de transaction pratiques et sécurisées.

Que ce soit pour l'usinage de précision, les applications structurelles ou les utilisations décoratives, les barres en acier inoxydable HAOSTEEL sont reconnues pour leur qualité et leurs performances constantes. Leur résistance exceptionnelle à la rouille et leur finition polie en font des barres de meulage polies en acier inoxydable et des barres brillantes en acier inoxydable idéales dans un large éventail de scénarios, de la fabrication industrielle à la conception architecturale.

Personnalisation :

HAOSTEEL propose des produits de barres en acier inoxydable de qualité supérieure, notamment des barres noires en acier inoxydable, des barres en acier inoxydable et des barres brillantes en acier inoxydable, adaptés pour répondre à vos exigences spécifiques. Notre gamme de produits couvre une grande variété de modèles tels que 201, 202, 301, 304, 304L, 316, 316L, 310S, 321, 347H, 317L, 316Ti, 2205, 2507, 904L, 410, 420, 430 et 430F.

Originaires de JIANGSU, nos barres en acier inoxydable sont certifiées selon la norme ISO90001, garantissant les normes de qualité les plus élevées. Nous offrons une personnalisation flexible avec des diamètres allant de 1,0 mm à 530 mm, conformément aux normes internationales, notamment ASTM, AISI, DIN, EN, GB et JIS. L'état de livraison des barres est recuit pour garantir des performances optimales.

Notre quantité minimale de commande est de 1 tonne, avec des prix basés sur la communication et la négociation pour répondre au mieux aux besoins de votre projet. L'emballage est manipulé avec soin à l'aide d'un emballage en bois d'exportation pour assurer une livraison en toute sécurité. Les délais de livraison varient de 5 à 10 jours, avec un délai de livraison global de 7 à 15 jours, soutenu par une capacité d'approvisionnement robuste de 5000 tonnes par mois.

Pour votre commodité, nous acceptons plusieurs conditions de paiement, notamment T/T, L/C et Western Union. Que vous ayez besoin de nuances ferritiques telles que 304, 201, 304L, 321, 310S, 347H, 316, 316L, 2205, 2507 ou 904L, HAOSTEEL garantit une personnalisation précise et une livraison fiable de barres noires en acier inoxydable, de barres en acier inoxydable et de barres brillantes en acier inoxydable pour répondre aux exigences de votre industrie.

Emballage et expédition :

Nos barres en acier inoxydable sont soigneusement emballées pour assurer une protection maximale pendant le transport. Chaque barre est enveloppée dans une couche protectrice pour éviter les rayures et les dommages de surface.

Les barres sont ensuite placées en toute sécurité dans des caisses en bois robustes ou des boîtes en carton renforcé, en fonction de la taille de la commande et de la destination, pour assurer la stabilité et éviter les mouvements pendant l'expédition.

Pour plus de sécurité, des dessiccateurs sont inclus pour contrôler l'humidité et prévenir la corrosion.

Nous proposons diverses options d'expédition, notamment le fret aérien, le fret maritime et le transport terrestre, adaptées pour répondre à vos délais de livraison et à vos exigences budgétaires.

Toutes les expéditions sont accompagnées d'une documentation détaillée, notamment des listes de colisage, des certificats de qualité et des certificats de conformité pour assurer un dédouanement en douceur.

Notre équipe logistique surveille chaque expédition jusqu'à ce qu'elle atteigne votre emplacement désigné, assurant une livraison rapide et sûre de vos barres en acier inoxydable.

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!